In today’s world, technology has made huge advancements in all walks of life. The apparels industry is one such industry that has been considerably improved by the use of technology.

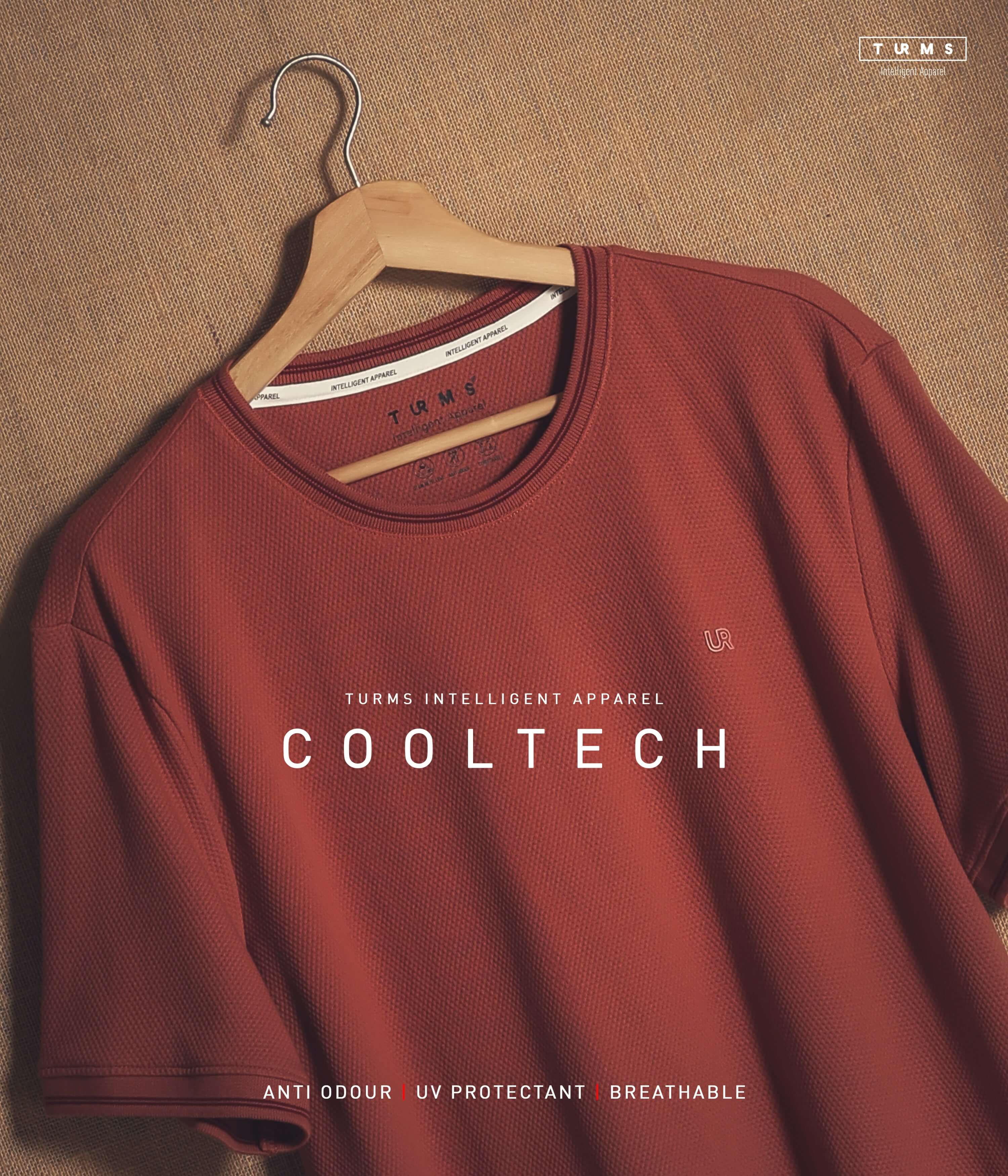

It is now possible to create virtual prototypes of clothing using computer-aided design (CAD) software, which can then be tested for fit, function, and performance. 3D body scanning technology has made it possible to create customized clothing that fits perfectly and performs to the specific needs of the wearer. The use of electronics in textiles now allows "smart" garments to track vital signs, sense the environment, and provide haptic feedback.

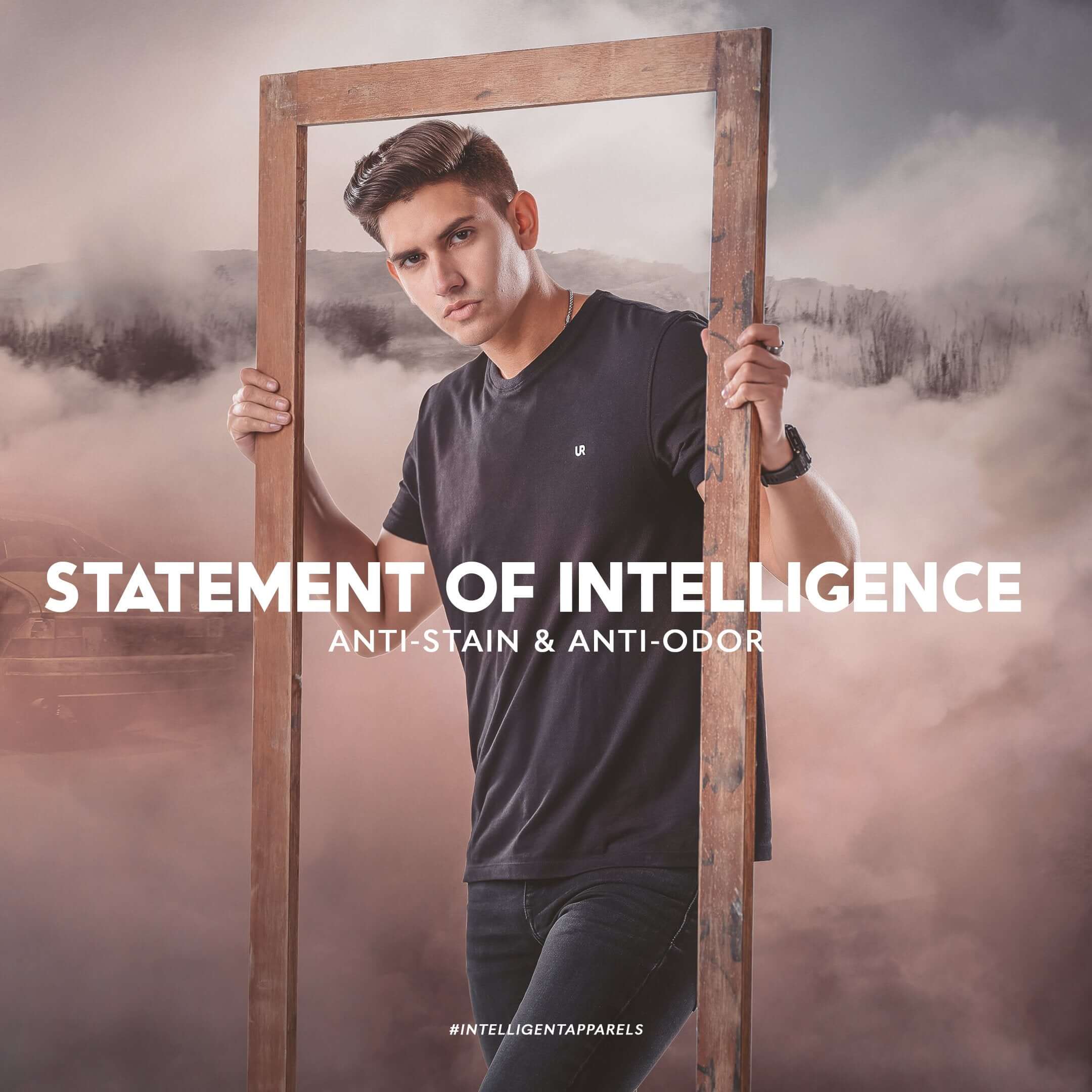

Advances in textile engineering have led to the development of new fabrics and fibres that have specific technical properties. Improvements in finishing techniques have allowed for the application of various functional treatments to fabrics, such as water-repellent, wrinkle-resistance, and antimicrobial finish.

Overall, technology has enabled the apparel industry to create clothing that is not only stylish but also functional and performative. Leading to substantial growth of the industry as a whole.

But, with the continuous growth of the Apparels Industry, it is important to consider the impact that this growth has on the environment and the importance of sustainability.

The textile industry is known for its high-water consumption and pollution, as well as the use of chemicals and dyes that can harm both the environment and the workers involved in the production process. Additionally, the fast fashion industry, which prioritizes speed and low costs over sustainability, has resulted in a significant increase in textile waste.

The use of different speciality finish chemicals has imparted wonderful new characteristics to fabrics, leading to the making of Functional Apparels. But on the flip side, has also increased chance of environmental toxicity and increase in human health hazard.

However, technology is also being used to create sustainable solutions in the industry. For example, there are now textile recycling methods and technologies that have been used to recycle old apparels back into new fibers, thus considerably reducing the requirement of new raw materials. Similarly new dyeing techniques have been invented that use less water and fewer chemicals. Additionally, many textile manufacturers are beginning to use more sustainable materials, such as organic cotton and bamboo, which require less water and pesticides to grow.

Furthermore, smart textile is also gaining attention as an area of sustainable textile as it can reduce the use of energy and decrease the amount of waste. For example, clothes made with smart textile can monitor the wearer's vital signs and adjust their temperature accordingly, reducing the need for additional layers or heating systems.

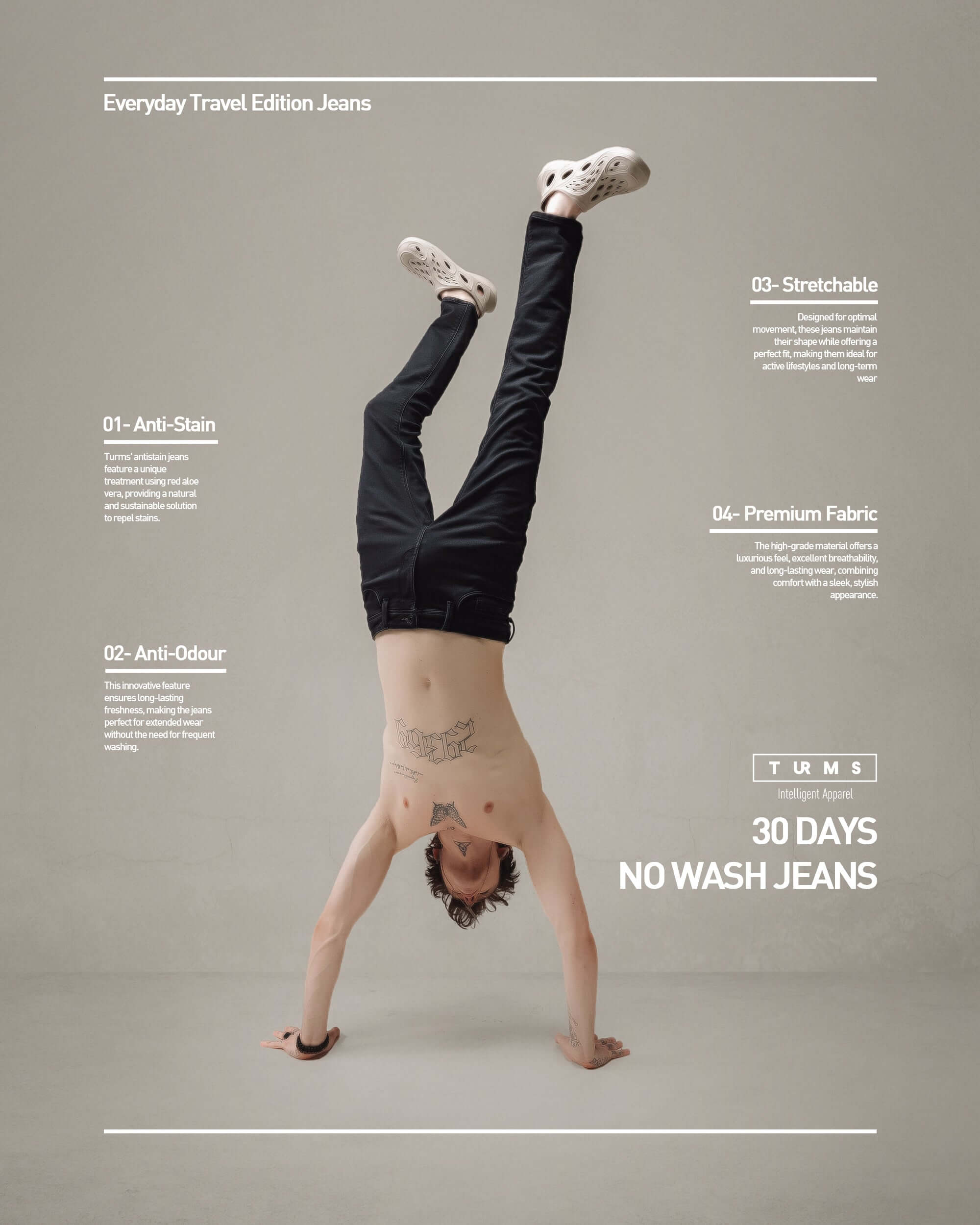

In the field of speciality finishes for Functional Apparels also, major improvements have taken place to improve the quality and durability of the speciality finishes on Apparels, over its lifetime, which undergoes harsh interaction with the environment and also have to undergo multiple washing cycles.

Most of these finishes have shown marked improvement over the years. However, one finish that is still a considerable challenge to master and perfect, is the Hydrophobic or Water Repellent Finish.

Traditionally, long chain Fluorocarbons have been used as Water Repellent Finish in all categories of Industry, where a water repellent finish had been desired. Due to the extreme low surface tension achieved by the long Fluorocarbon chains, water droplets turn into spherical droplets to reduce their surface tension, on coming into contact with fluorocarbon-based water repellent finish on a surface. Thus, they do not stay or absorb onto the surface and just roll off.

However, the long Fluorocarbon chains-based finish is a huge health hazard, as the chains do not easily break down inside the body. Thus, it can remain inside the human body and lead to the development of many carcinogenic disease such as different forms of cancer. Moreover, these fluorocarbon finishes, once carried to lakes and rivers, as sewage or waste from the manufacturing industries, pollute the environment and result in death of aquatic and land organisms, as they are not easily broken down naturally. Thus, becoming a great source of ecological toxicity.

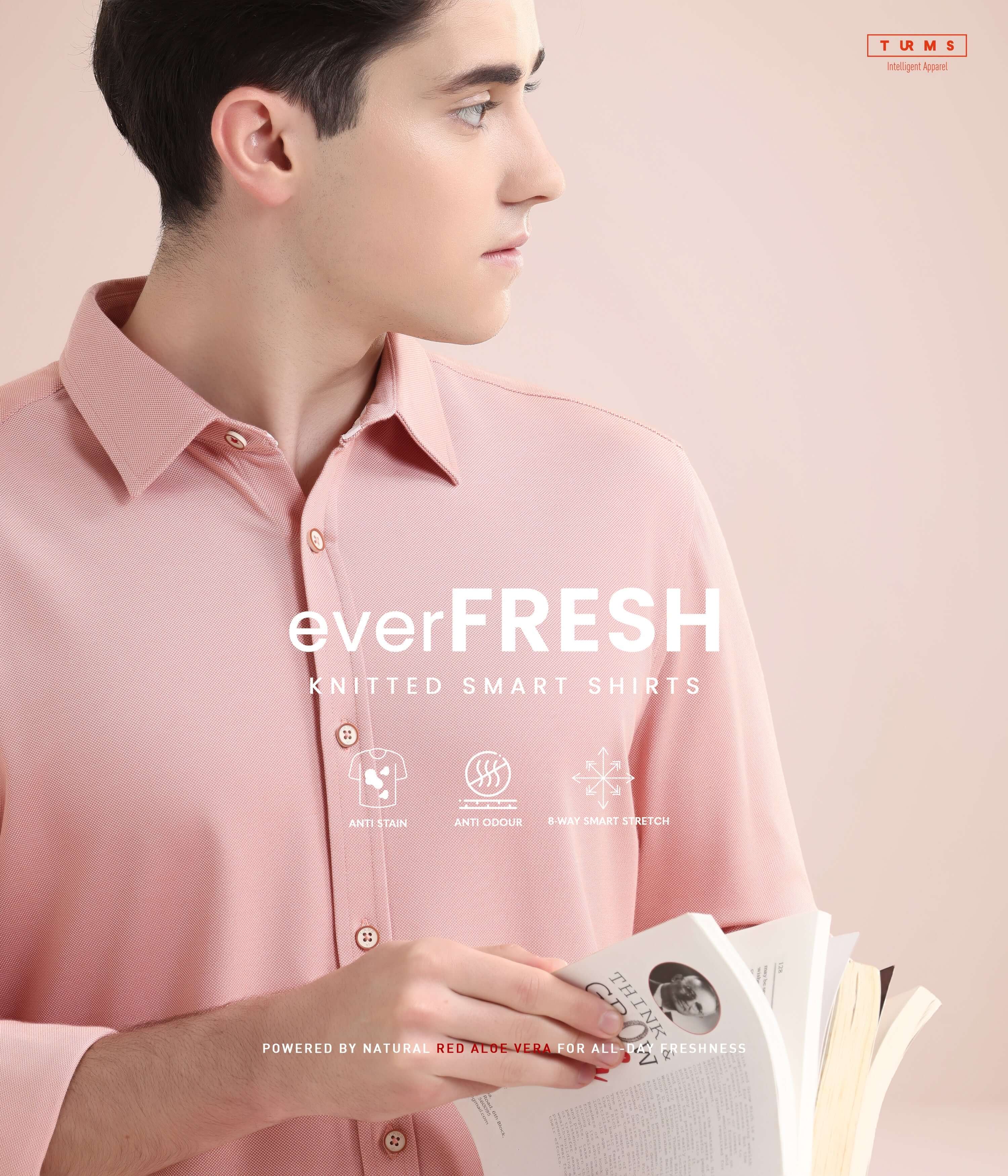

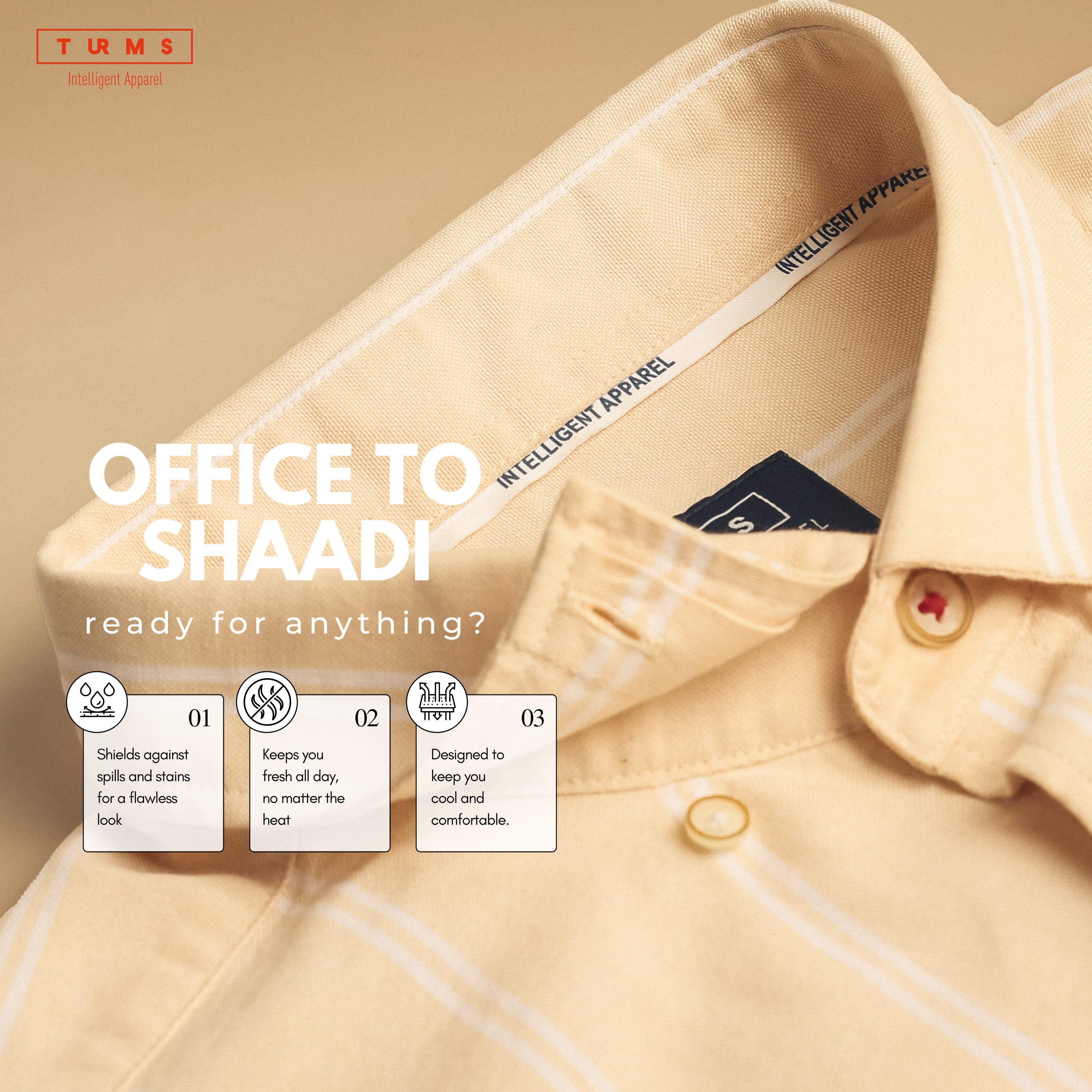

At Turms, contrary to our competitors, who use fluorocarbon-based water repellent finish, we have developed novel fluorocarbon free water repellent finish. Our Apparels are coated with proprietary hydrocarbon and silane-based water repellent finish, that are sustainable and non-toxic to humans or the ecology. We are proud to say that our water repellent apparels have been tested and accredited for safety by international testing labs such as TUV, Intertek for conforming to safety standards set by accreditation bodies such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals), GOTS (Global Organic Textile Standard) and OEKOTEX.

Thus, we are fully committed to our customers health and safety. Moreover, while other fluorocarbon free water repellent finish, wash away from the apparel after 5-10 washing, our anti stain property remains for 20 wash cycles(all water based stain easy to remove with minimal wash).

In this blog, we have just touched upon the use of technology in the origin of functional apparels. We have also discussed about our apparel’s water repellent property. In the next blog, we will talk about our apparel’s anti-odour and antibacterial property and its importance as functional apparels.